What are hinges? As one of the most commonly used and important hardware in the home, hinges are an essential part of the cabinetry. There are many types of hinges, including butt hinges, barrel hinges, piano hinges, pivot hinges, concealed hinges, etc. They have different appearance with different use. For aesthetically looking, concealed hinges have become one of the most popular hinge types in the market.

If you are looking for the right supplier of concealed hinges, it is necessary that you know well about hinges such as quality standards.

What Is Concealed Hinge?

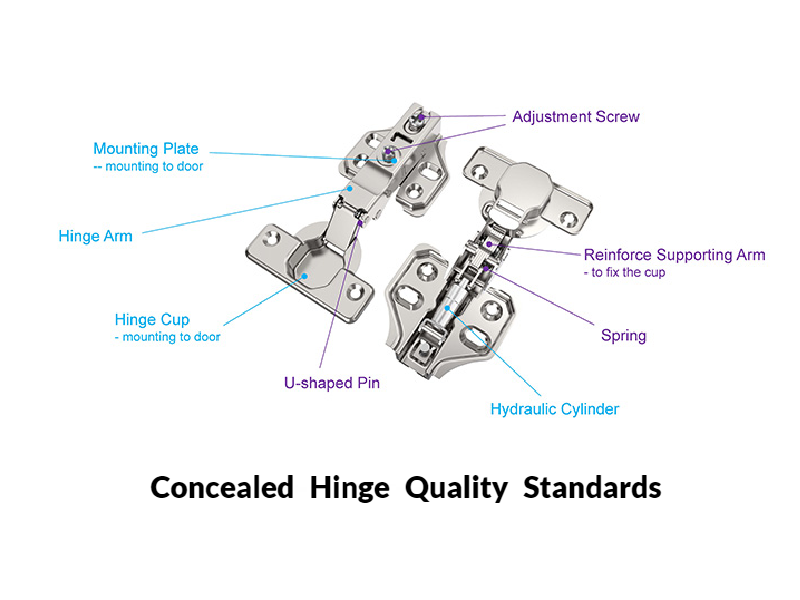

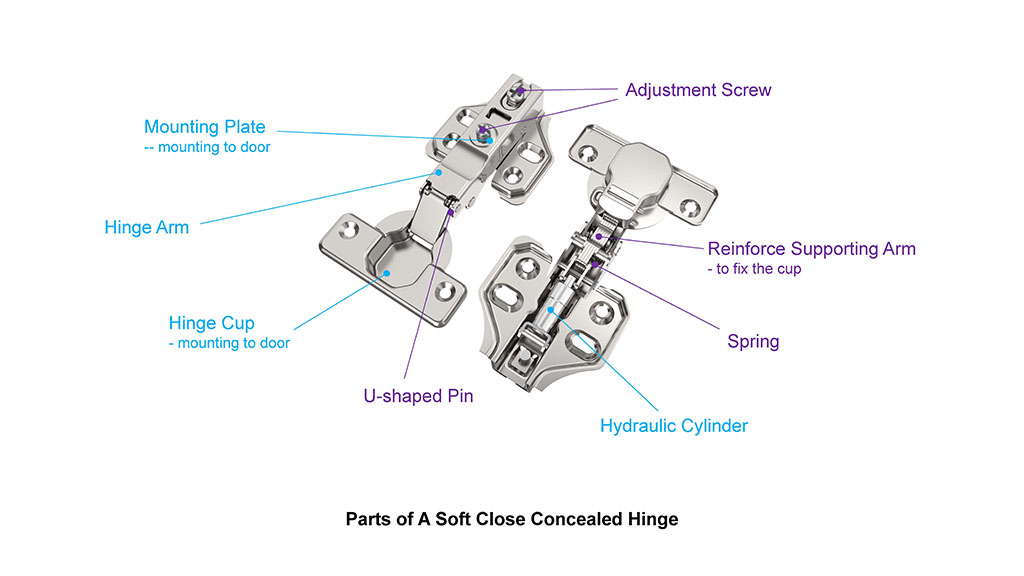

Concealed hinge is also called invisible hinge or European hinge. It lays flush inside the cabinet door and can be completely hidden when the door is closed. It helps to provide a smooth outer appearance to a cabinet. Apart from the aesthetic value, it makes it simpler to adjust the cabinet doors after being installed with the help of adjustment screws.

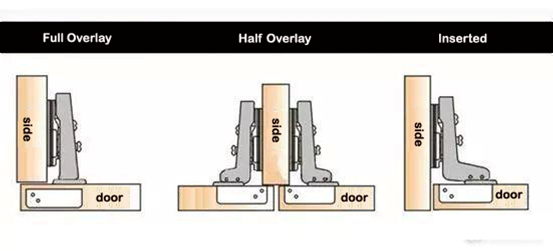

35 mm concealed hinges are most commonly used and come in a wide variety of types: fully overlay, half overlay, inset. The differences among these three types are their arms and the requirements for door mounting location.

Quality Control Standards of Concealed Hinges

-

Appearance

- The plating is free from visible colour differences, bumps and blisters.

- The cup and base plate are not blackened.

- The hinge surface is smooth and burr-free.

- All parts or joints should not be broken, deformed or worn.

-

Size and Weight

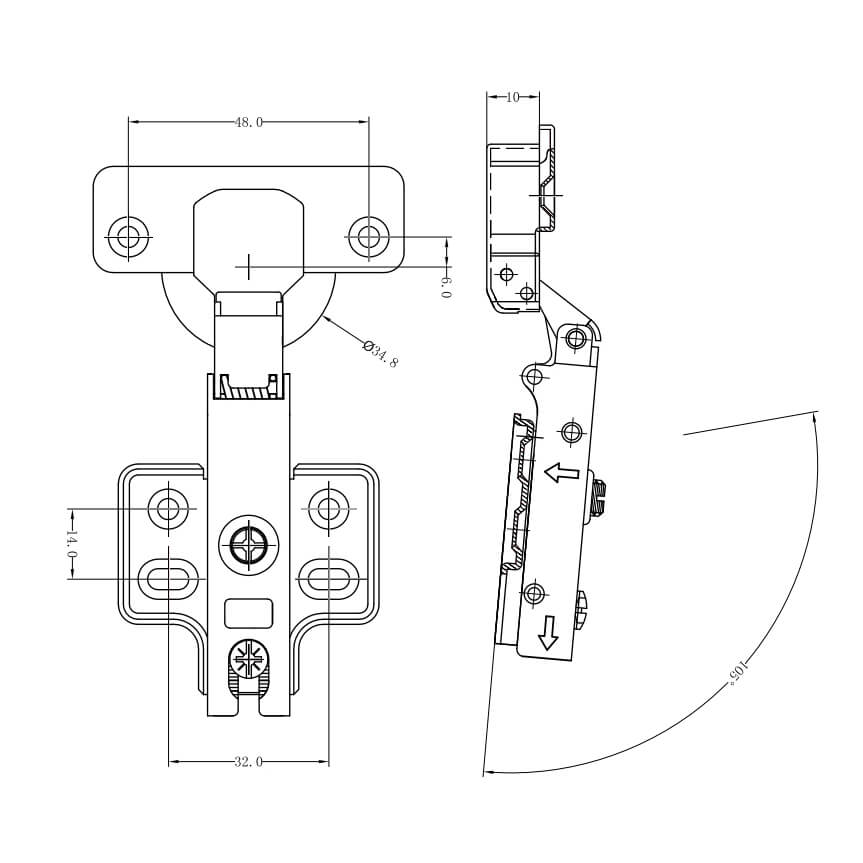

Diameter of Cup: 35mm (34.3±0.05 mm)

Distance from edge to hole: 37±1 mm

Diameter of Cup Hole: ±0.2 mm

Depth of Cup: ±0.3 mm

Effective Height of Base: N±0.5 mm

Opening Angle: ±3°

Length of Adjustment Screw: N±1 mm

Weight: N±2 g

-

Function

The cup of the hinge should be straight.

If there is a tilt of the cup, the angle should not exceed 1.5 degrees.

- The U-shaped pin should be in good condition

Open and close the hinge ten times in succession to ensure that the U-shaped pin is in good condition. The pin should not fall off when the hinge is knocked several times after the hinge side stands.

- The multi-piece reinforce supporting arm should have good strength.

Check the reinforce supporting arm to see if they are tightly riveted together. Press the arm with a pincer to see if it falls apart or break.

- The screws can be adjusted smoothly.

- The parts used for fastening or the fixed parts should not be loose.

All parts should function properly.

- The hydraulic cylinder should be leak-proof and hermetically sealed.

Oil leakage or oil seepage is not allowed.

-

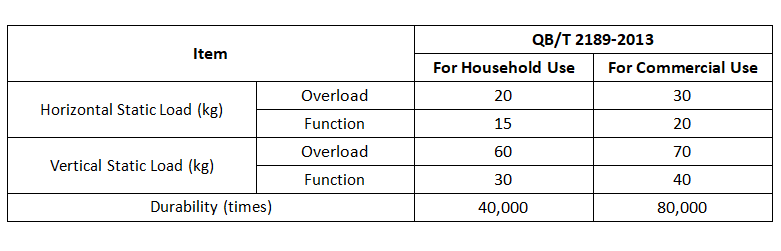

Load-bearing Capacity and Durability

It is estimated that a hinge is opened and closed on average more than 10 times a day. Therefore the load bearing and durability of hinges are also important factors to consider. Depending on the application, hinges can be divided into two categories: hinges for household use and hinges for commercial use. As commercial hinges are used relatively frequently and are more likely to be misused, the requirements are stricter.

According to QB/T 2189-2013 – the Chinese quality standard for the furniture hardware industry, the load-bearing and durability requirements for commercial hinges are significantly higher than those for household hinges.

-

Corrosion Resistance

Hinges are constantly exposed to air when in use. If the environment is too humid, it will be risky for the hinges to be corroded and damaged. Therefore, the corrosion resistance of hinges is also of importance.

Generally, a neutral salt spray test is required for hinges for 24 hours to check the corrosion resistance of the plating.

After 18h continuous spraying, the number of rust points ( d≤1.5 mm) per square decimeter should no more than 20. And the number of rust points ( d≥1.0 mm) should not exceed 5. Please note that the rust points within 2 mm of edges and corners are not counted. The test method is in accordance with QB/T 3826-1999 Light Industry Products Metal Plating And Chemical Treatment Layer Corrosion Resistance Test Method Neutral Salt Spray Test (Nss) Method Provisions.

Why Choose Venace?

Founded in 2011, Venace is a professional OEM furniture hardware and household products supplier from China.

Our production base covers an area of over 80,000 square meters, integrating R&D, OEM manufacturing, and packaging. More than 10 automated production lines ensure our strong production capacity. We carry out a strict quality control with ISO 9001 certification.

If you are looking for a reliable hinge supplier, contact us now! We can offer you competitive prices, premium quality, fast delivery, flexible production and strong marketing support.

The cup of the hinge should be straight.

The cup of the hinge should be straight.