Quality Standards And Problem Analysis of Hinges

Strength Requirements

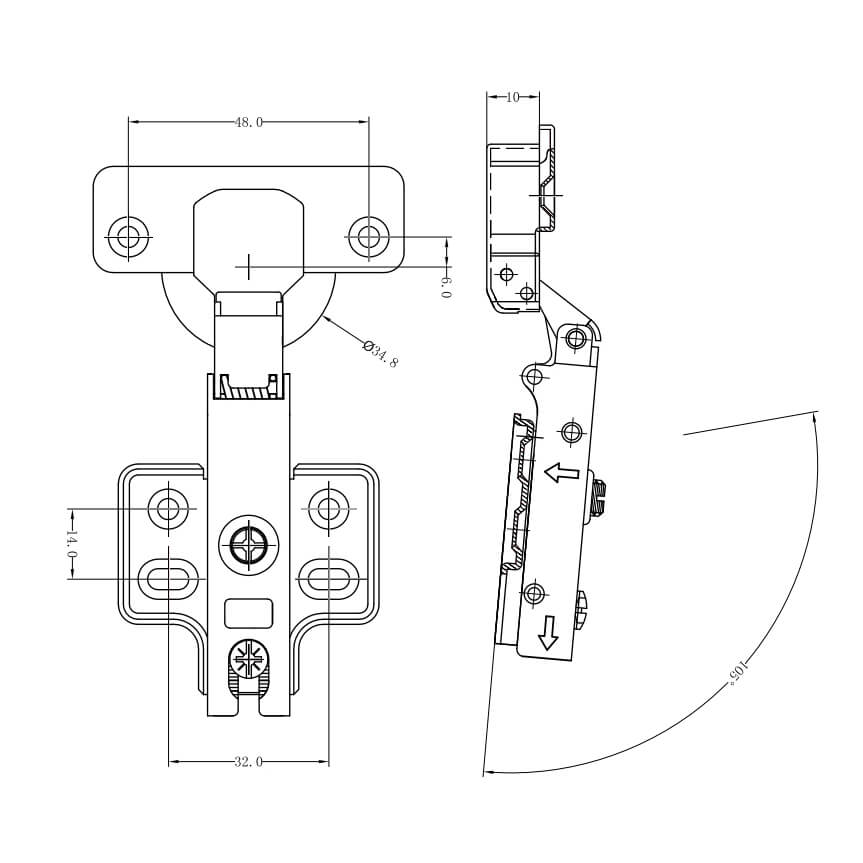

According to China’s current standard for cup hinges QB/T 2189-2013 Cup Hinges For Furniture Hardware, the strength indicators for cup hinges are mainly vertical static load and water calm load. They are tests of the ability of cup hinges to be subjected to vertical or horizontal forces during use without being damaged. QB/T 2189-2013 divides vertical static load and water calm load into functional and overload tests.

Vertical Static Load Test

Overload Requirements

- All components or joints should not break.

- The components used for fastening should not be loose, as confirmed by hand pressure.

- All components should not be deformed or worn in such a way as to interfere with normal operation.

- Fixed components should not be loose.

- The function of all components should not be impaired.

- The cup-shaped concealed press chain and its components should not be separated.

-

Test method:

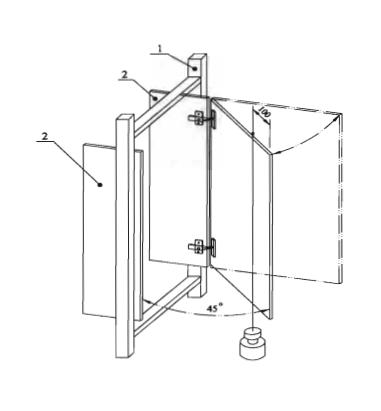

- Vertical Static Load Test: The specified load is suspended 100mm from the furthest side of the cup hinge, (as shown below) and the door is opened and closed 10 times each time from 45° from the fully closed position to 10° from the fully opened position, 1 cycle is counted, the maximum opening angle is 135° from the fully closed position. The door can be opened and closed manually, open and close time of 3s to 5s each.

- Horizontal Static Load Test: The test is only applicable to concealed cup chains with a maximum opening angle of less than 135°. In the fully open position, the specified load is applied to the horizontal centre line at a distance of 100 mm from the side of the cup dumpling chain in the direction perpendicular to the plane of the door and the test is performed IO times. The test is unloaded and checked at the end of the test.

Of these, overload horizontal static load and overload vertical static load are the main failed items.

The main reasons for failure are as follows.

- Loose screws cause the hinge to fall off. Generally hinges come with two types of screws. One type is the adjusting screw, including the upper, lower, front and rear adjusting screw. Some new hinges also have a left and right adjusting screw. Some of the new hinges also have left and right adjustment screws, which are now known as three-dimensional adjustment hinges. The other type is the base screw, which is mainly used to fasten the cup-shaped concealed hinge to the door. They are mainly used to fasten the hinges to the door frame and door panel. During testing, the screw ends were found to be poorly or unguided. The screws were found to be poorly guided or not guided at all. The threads are deformed when the hinges are installed in the door panel, causing the screws to slip during fastening; or the screws are not strong enough. If the screw material is not strong enough, it will also slip or even break, causing the screw to break. The hinges fall out of the cabinet during overload water calming load detection.

- The hinges are too thin and the hinge cups and hinge rods squeeze and deform each other after being loaded, resulting in a larger gap or overall sinking of the cabinet door

-

Solution:

The hinge body and screws are the main body of the hinge system. To ensure that the overload horizontal static load and vertical static load reach the standard, choosing the right base screws and hinge thickness is key. The base screw must be of sufficient length and strength to avoid slipping during use. The hinges should not cut corners on the materials used. Adequate thickness is a guarantee of the hinge’s strength.

|

Type Of Furniture |

Test Door Type | Horizontal

Static Load/kg |

Vertical Static

Load/kg |

Durability/Time |

|

Household |

A | 15 | 30 | 40,000 |

|

Commercial |

20 |

40 |

80,000 |

|

|

Household |

15 |

– |

40,000 |

|

| Commercial | 20 | – |

80,000 |

Durability Requirements

According to statistics, cup hinges are opened and closed on average more than 10 times a day during the use of furniture, and QB/T 2189-2013 divides the durability test for cup hinges into domestic and commercial models, with 40,000 tests for domestic models and 80,000 tests for commercial models.

-

Test Method For Durability

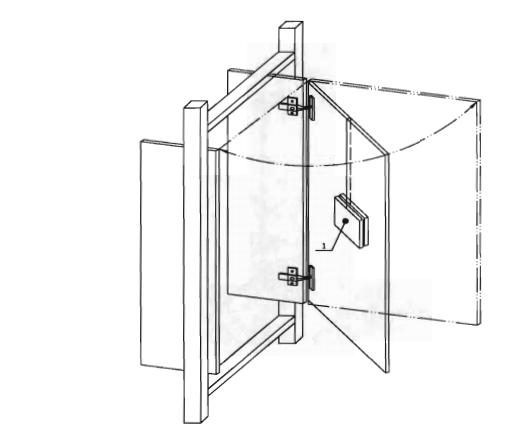

Hang two 1 kg of items on each side of the door on a straight centre line (see diagram below) for the required number of cycles. Open the door to a maximum angle of 130° and close it with a back and forth reciprocating movement. No internal resistance should be generated when the door is in the open position. Check at the end of the test. If the cup hinges do not have a damper or positioning device, the door should open and close slowly during the test, with the door opening and closing times being approximately 3s each in each cycle, with a recommended maximum frequency of 6 times/min. If the cup hinges have a damper or positioning device, the damper or positioning device should correctly fulfil its function with each reciprocation.

-

Failures:

- The door does not close tightly or does not open smoothly

- Springs deformed or hinges cracked

-

Reason analysis:

Due to insufficient spring material performance and too thin hinge thickness, the hinge cups and hinge rods are extruded and deformed by each other after being loaded. Therefore, the door gap becomes bigger or the whole cabinet sinks.

-

Solution:

Select a spring with high elasticity and a thicker hinge.

Durability Test

Corrosion Resistance Requirements

Currently, there are several materials available for cup hinges installed on furniture, such as stainless steel, nickel-plated steel and nickel-chrome-plated steel. These materials are exposed to the air and with changes in temperature and humidity in the air, rusting and corrosion may occur, thus affecting the overall quality of the furniture product. In particular, the hinges installed in the cabinets, due to long-term exposure to humidity and grease and smoke environment, are very easy to affect the life of the hinges due to rusting, resulting in the entire cabinet door opening and closing stuck or even off.

- Requirements:

After 18h continuous spraying, the rust point below 1.5mm is ≤20 points/dm2, of which ≥1.0mm rust point does not exceed 5 points (not counting within 2mm from the edges and corners), test method are as QB/T 3826-1999 Light Industry Products Metal Plating And Chemical Treatment Layer Corrosion Resistance Test Method Neutral Salt Spray Test (Nss) Method Provisions specified.

- Test method:

the same as the acid salt spray test with more stringent environmental requirements. The 24-hour acetic acid salt spray test is used to test the corrosion resistance of the product in a humid, hot and weakly acidic environment, which matches the actual environment in which the hinges are used as the kitchen hardware.

- Failures:

Many cup-shaped concealed hinges showed corrosion spots of varying sizes on the surface of the hinges after the salt spray test, especially on the connecting piece and at the screw and screw ports.

- The main reason for this is that the plating may be uneven or the electroplating process may not be properly controlled.

- The main ways to solve and improve the corrosion resistance of hinges:

- Improve the plating process to ensure the uniformity of the plating layer.

- Select a metal plating with excellent corrosion resistance and ensure the thickness of the plating.

- Use rust prevention oil

Hydraulic Performance

Soft close hinge is a kind of anechoic damper hinge that uses high-density oil to achieve the ideal soft closing by directional flow in a closed container. Hydraulic hinges are becoming more and more widely used because they close softly and silently. However, soft close hydraulic hinges are available on the market in varying quality. During testing, it was found that a great number of hydraulic hinges had oil leaks or hydraulic cylinder bursts after durability testing. The hydraulic damper is the core component of the hydraulic hinge. The wear resistance, toughness and force area of the hydraulic damper cylinder material are the main factors that determine whether the hydraulic hinge damper is durable. Hydraulic hinges in the hydraulic damper by material, there are made of steel, copper, but also nylon made. In the acidity of the kitchen environment, copper or steel dampers are easy to rust oxidation and damage the damping mechanism of the hinges for a long time.

How To Choose the Right Hinge For Your Home?

Good hinges are made of alloy in one stamping, with a thick feel and a smooth surface. Because of the thick surface coating, so this kind of hinge is solid and strong, not easy to rust with a strong load-bearing capacity. This makes the cabinet door open and close freely and tightly. For consumers, it will be difficult for them to select the hinges. In addition to observing the appearance and the surface of hinges, consumers tend to choose brand hinges. However, branded hinges are also partly authorised OEMs and the quality can not always be guaranteed. So, it can be difficult for consumers to choose the cost-effective hinges. As a designer, I have given some advice by disassembling and testing the various hinges on the market in a comprehensive comparison. There are some factors to consider when choosing hinges especially hydraulic soft close hinges for your home.

- Finish

Take a few hinges and look at them to see if the hinges look roughly the same. Poor quality hinges have uneven surface plating, especially at the deep corners of the hinge cup and the back of the hinge, where the plating is thin and not smooth and the hinge is partially discoloured, making it easy to rust.

- Hinge Cup

Take the hinge cup and slowly close the hinge as if it were a door. Remember to be slow. If you feel that the hinge opens and closes smoothly and if you can do this for several consecutive tests, then the hinge is prima facie satisfactory. If the hinge opens and breaks outward with a loose or strange sound, it means that the hinge is not accurate enough and the quality is not good.

- Strength

See how the sample hinges are stressed on site. Directly press the door panel down, if it feels very stable, it proves that the hinge strength is relatively good.

- Screws

Use a screwdriver to check the screws. Check that the adjustment screws on the hinges and the fastening screws at the end of the hinges are smoothly tightened. Details reflect the strength of the manufacturer.

- Lubricants

Choose the hinges with top-quality yellowish or cream coloured lubricants. Hinges that use top quality yellowish or cream coloured lubricants on the springs have a long life. Cheap lubricants in black and yellow or plain white colours dry out easily. On hot days, the viscosity of this low-quality lubricant is so low that you can feel your hands full of oil after taking the hinge.

Quality hinges are generally a little stiffer and the adjustment screws are tightly fitted. When using a hinge for the first time, only a screwdriver can unscrew the adjusting screws, while many general hinges do not fit tightly enough and can be turned by hand.

- Hinge Springs

The hinge springs are smooth and neatly finished on the edges. Good quality hinges have a special nylon protection device. Many general hinges have no polished edges and have burrs.

- Weight

In general, you cannot tell the material thickness of a hinge. You can distinguish this by the weight of several hinges of the same type together.

- Flat Cross-section

Look at the cross-section of the hinge to see if it is flat, especially if there are signs of cracking in the section of the deformed part. If there are obvious creases, it means that the product is of average quality.

- Welded Spots

Look for welded spots or areas where there are serious local polishing marks. Most of the hinges are forged or stamped into shape. If there are welded spots, it means that the material cracked during the stamping process. So the material used may not be up to standard.

- Base

The hinge body and screws are the main body of the hinge system. To ensure that the overload horizontal static load and vertical static load reach the standard, choosing the right base screws and hinge thickness is key. The base screw must be of sufficient length and strength to avoid slipping during use.