Description

Best Quality Gas Spring of Professional Gas Spring Manufacturer

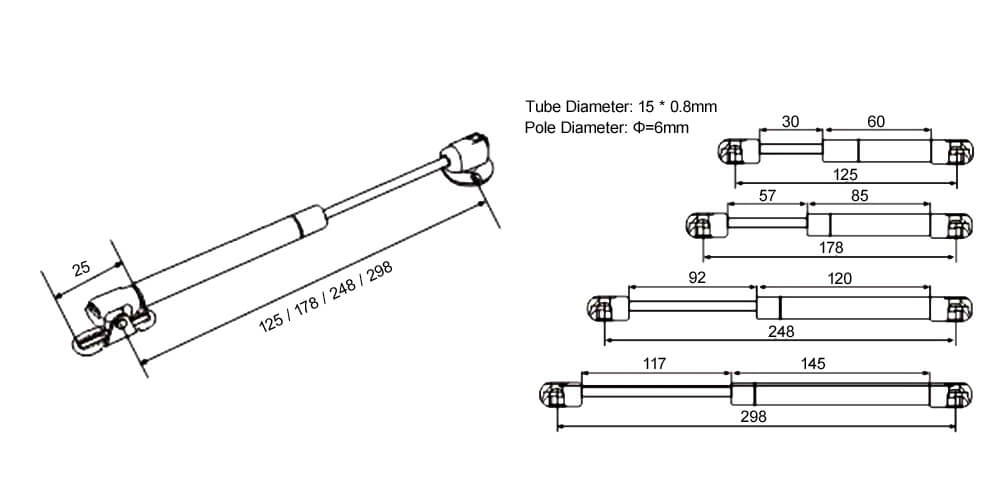

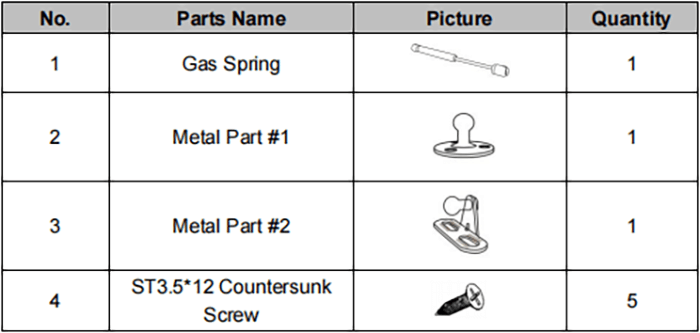

SKU | Product Name | Pipe Length (mm) | Stroke (mm) | Distance toCenter (mm) | Net Weight (g) |

44.43.01100106 | 6” Lift Support Gas Spring | 60 | 30 | 125 | 85 |

44.43.01100108 | 8” Lift Support Gas Spring | 85 | 57 | 178 | 95 |

44.43.01100110 | 10” Lift Support Gas Spring | 120 | 92 | 248 | 110 |

44.43.01100112 | 12” Lift Support Gas Spring | 145 | 117 | 298 | 118 |

44.43.01100206 | 6” Down To Support Gas Spring | 60 | 30 | 125 | 88 |

44.43.01100208 | 8” Down To Support Gas Spring | 85 | 57 | 178 | 100 |

44.43.01100210 | 10” Down To Support Gas Spring | 120 | 92 | 248 | 114 |

44.43.01100212 | 12” Down To Support Gas Spring | 145 | 117 | 298 | 130 |

Gas Spring Manufacturer

SKU | PCS/ | Net Weight/ | Gross Weight/ | Package Size | PCS/ | PCS/ | PCS/ |

44.43.01100106 | 100 | 8.5 | 8.7 | 310*220*230 | 178500 | 264300 | 298800 |

44.43.01100108 | 100 | 9.5 | 9.7 | 310*220*230 | 175200 | 237100 | 268000 |

44.43.01100110 | 100 | 11.0 | 11.2 | 310*220*230 | 151700 | 205300 | 232100 |

44.43.01100112 | 100 | 11.8 | 12.2 | 310*220*230 | 139300 | 188500 | 213100 |

44.43.01100206 | 100 | 8.8 | 9.0 | 310*220*230 | 178500 | 255500 | 288800 |

44.43.01100208 | 100 | 10.0 | 10.2 | 310*220*230 | 166600 | 225400 | 254900 |

44.43.01100210 | 100 | 11.4 | 11.7 | 310*220*230 | 145200 | 196500 | 222200 |

44.43.01100212 | 100 | 13.0 | 13.2 | 310*220*230 | 128700 | 174200 | 196900 |

What is a gas spring?

As a gas spring manufacturer, let’s introduce ABC of gas spring for you. Cabinet gas spring is suitable for supporting cabinet components, balancing gravity, replacing mechanical springs of fine equipment, etc. It has been widely used in woodworking machinery, etc. Pneumatic gas springs are powered by high-pressure inert gases. When in use, constant support force and the damping mechanism of the gas spring help prevent slamming. This is the biggest feature that makes gas springs better than ordinary springs. Moreover, it is easy to install, safe to use and doesn’t require maintenance.

How does it work?

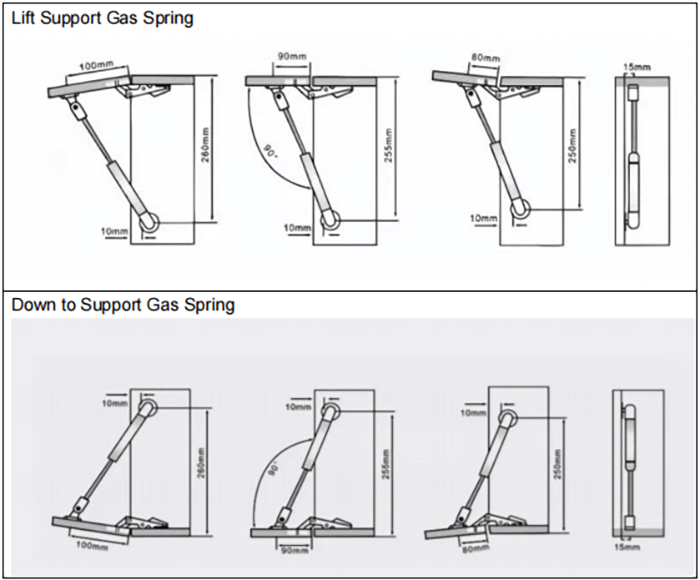

There are two types of gas springs for cabinets — lift support gas spring and down to support gas spring, which have different working principles and structures. In this article, I will tell you how a gas spring works by taking the lift support gas spring as an example.

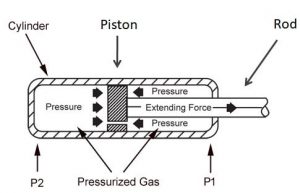

Figure 1 Structure of Gas Spring

As shown in figure 1, a gas spring consists of a cylinder filled with high-pressure inert gas, a piston, a rod, and a seal. When the piston is pushed inward, The gas in the rodless part of the cylinder enters the part with the rod through small holes in the piston, making the pressure equal on both sides of the piston. However, the rod will squeeze the space of the gas inside the cylinder once it enters the airtight cylinder. According to Boyle’s law, as the volume of gas inside the cylinder becomes smaller, the pressure inside the cylinder is larger than that at the starting position. When the piston reaches the P2 position as shown in figure 1, the pressure in the cylinder is maximum. The holes in the piston make the pressure on both sides of the piston equal, but the pressure difference formed by the different force areas on both sides pushes the piston to position P1. this constant pressure difference enables the gas spring to have a stable support force.

Damping

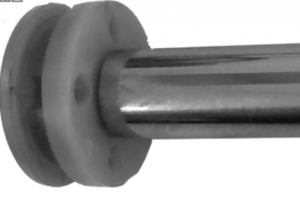

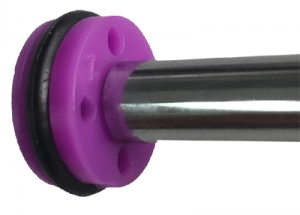

The thrust of the gas spring is generated by the pressure difference between both sides of the piston inside the cylinder with different force areas. The gas pressure can be in equilibrium by the -holes in the middle of the piston. However, this equilibrium is not achieved in an instant. The diameter of the holes directly affects the time to reach the balance. By controlling the flow of the gas, the effect of damping can be achieved. Most of the gas springs for cabinets have asymmetric holes in the pistons. Multiple open -holes will speed up the movement of the piston from position P2 back to P1. When pushing the rod from position P1 to P2, there is only one hole – open to slow down the piston movement. So we can quickly open the door, and close the cabinet door relatively slowly to avoid impact and slamming.

|  |

Figure 2: Air Holes of the Piston

Why should the cylinder be filled with nitrogen instead of air?

To make the smooth movement of the piston, the inside of the cylinder is coated with a layer of lubricant. Air consists of 78% nitrogen, 21% oxygen, and 1% other gases. If the cylinder is filled with air, oxygen will react with the lubricant, causing the lubricant to dry up and condense after being used for a time, and the piston will not be able to slide smoothly in the cylinder. As an inert gas, nitrogen will not react with the lubricant. So the nitrogen in the cylinder ensures more stable performance of the product.

Notes on the Use of Gas Springs – By Professional Gas Spring Supplier

- The gas spring shall not be exposed to excessive heat or open flame since it is filled with high-pressure gas.

- The gas spring shall be installed in a way that the rod can always point downward during use. By keeping the seals in the cylinders oiled at all times, there will be less wear and leakage of oil, ensuring optimal function and life.

- The piston may not be sealed if the piston rod is slightly scratched, paint dusted bent, etc.

- Do not use a gas spring lift with tiny dents or bends in the cylinder. A damaged cylinder can pose safety risks.

- Gas springs lift are applicable in ambient temperatures between -30°C and +80° If possible, do not use the gas spring intensively at the extremes of this temperature range. The support force of the gas spring will decrease or increase with the change of ambient temperature.

- Choose as large a cross-section of gas spring as possible to avoid radial forces (lateral forces) since gas springs are to handle axial loads.

- Do not lubricate the piston rod with grease or oil. Do not immerse the gas spring in oil or solvent.

- Do not use non-stainless steel gas springs in corrosive environments.

If you are looking for a gas spring manufacturer, please do not hesitate to contact us to make an inquiry.

Base.P –

Excellent gas spring lift!