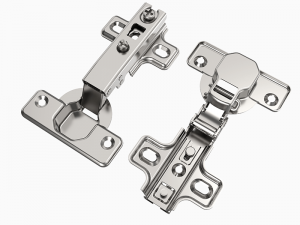

How to Make A Hinge: Materials and Production Process

The hinge manufacturing process follows several steps. Hinges are used in a wide range of applications. They are used to connect kitchen cabinets with the doors. Having the right hinges assures homeowners excellent durability when it comes to kitchen accessories. The kitchen tends to experience a high level of moisture; it is essential to get rust-resistant hinges. Different treatments can be applied to the hinges to bring about rust resistance. Some metals, such as brushes, are known to have an attractive finish; they can be used to enhance the aesthetic appeal in a given home. Choosing the perfect hinges contributes to the perfect project completion.

Hinge Materials

Different manufacturers apply stamp hinges to distinguish their products from others. There are several materials used to make the hinges. Check out eh stamp hinges product details, and you will know the materials used to make a given hinge. Some materials are more durable and reliable in making hinges. They tend to attract more costs than others. When renovating a kitchen, going for the perfect hinges is essential. Common materials sued to make the hinges are:

-

Steel

Many affordable hinges in the market are made out of steel. They can rust if used in places where they get into contact with water often. Several treatments can be applied, such as painting, to make them more durable. Some people prefer the application of rust-proofing tactics to make the hinges last longer.

-

Stainless steel

It is another common material that is used to make the hinges. Areas such as the kitchen require hinges that will not rust. Stainless steel tends to be highly resistant to trust. It can be applied in the kitchen to make the cabinet doors last longer. The hinges can be managed to meet different specifications. Some projects require long hinges; the experts should check out the type of fixtures where the hinges are required before they can order. They are available in different specifications to realize the best results in different projects.

-

Brass

It is another matter that is applied to make the hinges. The materials offer the perfect finish. Projects where great aesthetic appeal is required, can rely on the brass to realize the perfect project completion. Bras is easy to work on; it can be worked into different shapes to get the right designs of hinges. They may tend to be a bit expensive, but they can assure hoe mowers the perfect look.

Hinge Production Processes

There are several processes involved in the hinge manufacturing process. It is a complex process that requires several types to accomplish. The manufacturers have developed a complicated process to automate the hinge manufacturing process. The hinges will follow the following steps to get the work down perfectly. Some of the steps followed in the hinge manufacturing process are as follows:

-

Extrusion

The technique applies high pressure to force the metallic part in the die. The die allows the hinges to form into different shapes. When the extrusion process is applied to manufacture hinges, the results are high-quality stamped hinges. The hinges are a bit expensive, but they are of the highest quality to meet the needs of a wide range of people.

-

Deformation

The process involves bending, rolling, spinning, and forging the materials to form the hinges. In most cases, it applies special machines that simplify the whole process. Other methods that can be applied to achieve the best results are stretching and applying to punch to achieve the best results. The high-quality features assure the manufacturing team of the perfect hinges for a wide range of applications.

-

Cutting

It involves removing excess materials from the metal workpiece. The hinges are made out of large metal parts. The application of cutting techniques plays a crucial role in removing the hinges from the remaining metal parts. The process can seem simple, but it is highly effective in removing excess parts from the metals.

Secondary Processes

After the hinge manufacturing process is almost complete, several secondary processes keep the hinges in beautiful shape. The hinges will be seen by people who enter the house. The application of the secondary processes is essential to make the hinges achieve the best results. Here are common processes applied to finish the hinge manufacturing process.

Common Hinge Manufacturing Processes

-

Ball bearings

Some hinges are fitted with ball bearings to make them slide over each other smoothly. The application of the ball bearings is crucial in making it easy to open the doors. Hinges are used to connect two parts in an assembly. In most cases, they are used to connect doors. The smooth movements are essential to simplifying the process of closing and opening doors.

-

Painting

Application of paint is another process that is utilized after the manufacture of the hinges. Materials such as steel are known to rust.

The application of paint creates a seal that is crucial in reducing the rate of corrosion. The paint is also essential in making the hinges achieve some form of aesthetic appeal.

-

Burnishing

It involves rolling the hinges against other metals. The rubbing process created is essential in making the hinges get the perfect look. Application of the burnishing process is essential in creating the perfect look for the hinges. They will improve the aesthetic appeal of any home accessory where they are fitted.

-

Polishing

Polishing involves creating the perfect finish on the hinges. There are several processes involved in the polishing process. The manufacturers will have to check out the type of metal applied in making certain hinges before coming up with the right polishing process. It is an effective way to make the hinges stay perfect. The manufacturing team can as well apply smoothing methods that will lead to the creation of the perfect finish.

-

Rust-proofing

The process involves the application of rust treatment procedures on the hinges. The hinges will be exposed to elements of weather in their operations. The application of rustproofing methods is essential in making them last longer.

The hinge manufacturing process follows several steps. It is essential to buy hinges manufactured to meet the highest quality standards to realize value for money in the long run.