Hinge Manufacturing Process

As an important hardware accessory for kitchen cabinets, hinges can be found everywhere in domestic life. The quality and practicality of hinges can affect the normal use of a cabinet. Hinges are available in different materials, types, functions, surfaces, and prices, which can vary in terms of production processes. However, modern production processes make the production process similar. Standard production lines guarantee the quality, manufacturing efficiency, and mass production of hinges to meet the huge demand of the market. To source high-quality hinges, it is essential to understand the process. In this article, we will introduce you to the types of hinge materials and the manufacturing process of hinges.

Types of Hinge Materials

- Steel Hinges: Steel is one of the most common metals used for hinges due to its durability. Steel can be alloyed with other metals, such as chromium and nickel to produce stainless steel, which has a high resistance to rust.

- Brass Hinges: As an alloy of zinc and copper, brass is another common raw material for hinges. The gold-colored appearance of brass hinges makes them decorative hardware.

- Bronze Hinges: Bronze is also an ideal material for decorative hinges. With its red surface, bronze is often used in small hinges.

- Plastic Hinges

Hinge Production Processes

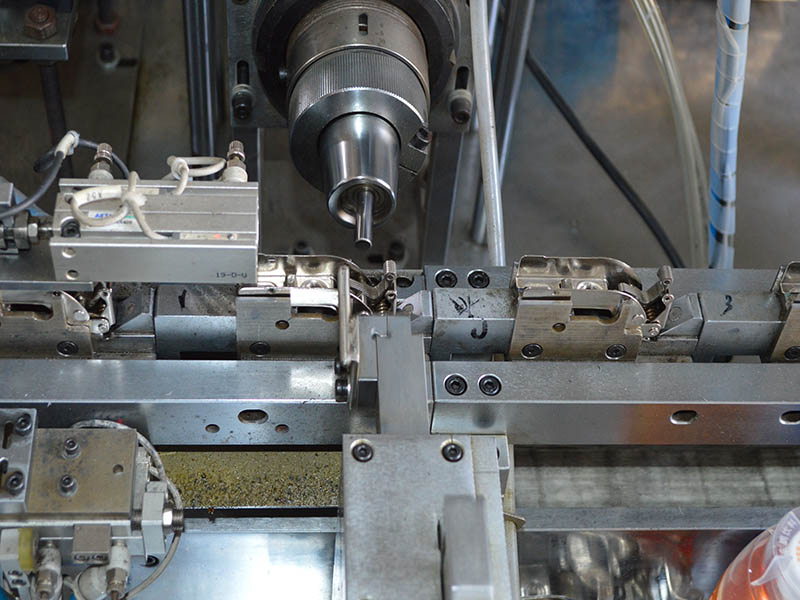

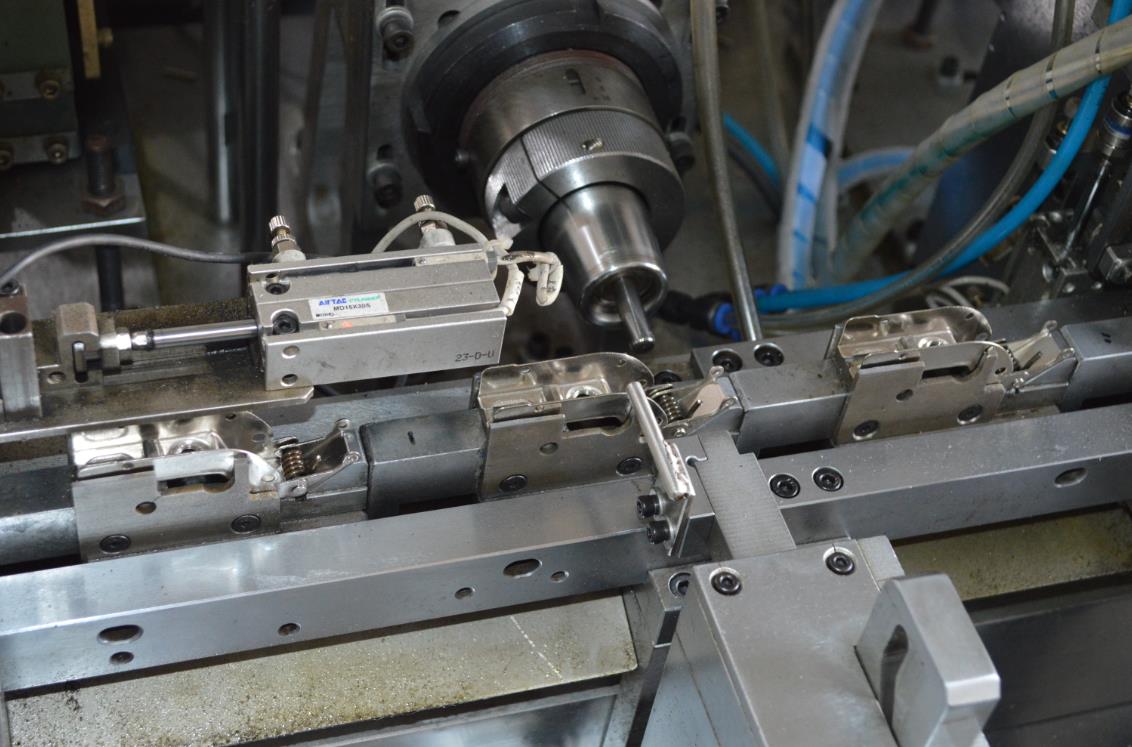

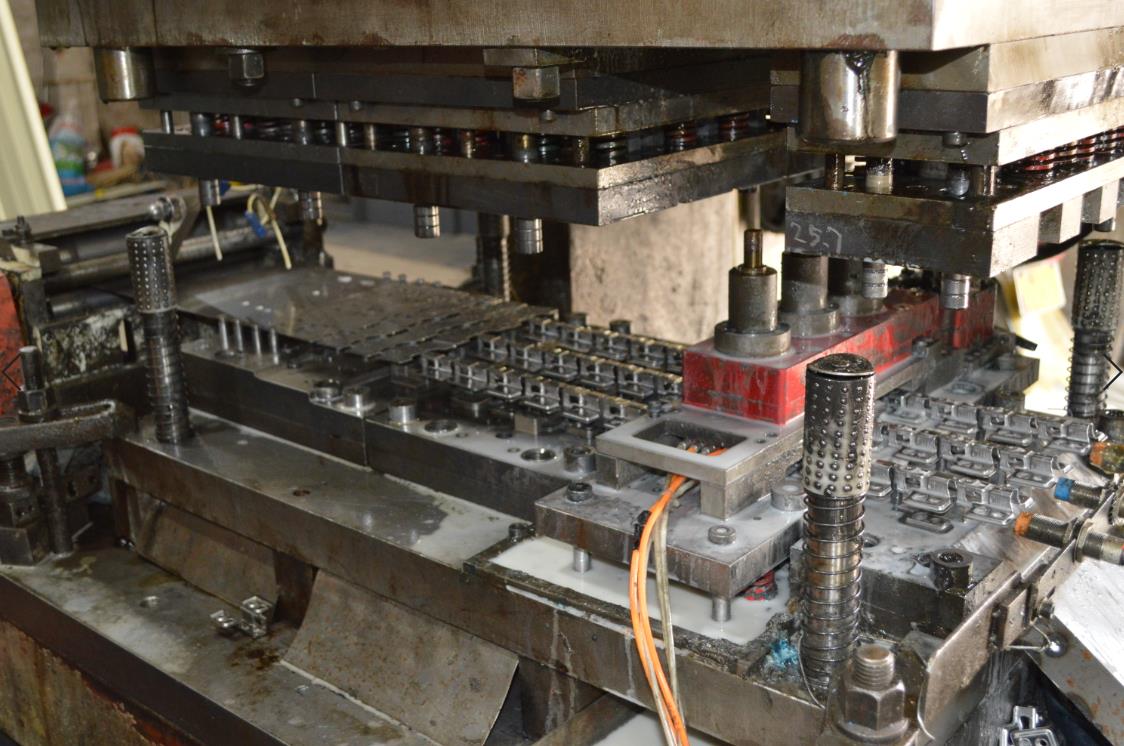

Generally speaking, the cost of a hinge depends on the production process and its efficiency. Stainless steel hinges manufacturing process – The production of hinges involves heat treatment of the raw material, stamping, cutting, flattening, and deforming the workpiece. Through a series of processing steps, the shape and chemical composition of the metal material is changed, resulting in a usable hinge component.

- Casting: Casting is a common processing technique used in hinge production. The molten metal is first poured into a mold and solidified into the desired hinge shape. After a polished or honed finishing process. The hinge component will then acquire a fine appearance. It is worth noting that finishing by hand casting can make hinges much more costly.

- Extrusion: Extrusion is another common process, but often results in higher production costs. Under high pressure, the metal workpiece is pressed against a die to form the special shape of the hinge. Compared to stamped hinges, hinges that have been extruded are stronger and thicker, but also more expensive.

- Deformation: Deformation is a processing technique that allows the metal to be deformed into the shape of a hinge. By bending, rotating, rolling, or forging, the metal is drawn and stretched to the desired shape. The size of the workpiece can then be changed using a turret punch.

- Cutting: Cutting is a technique for removing excess material from a metal workpiece. It is another method of shaping them into hinged parts. By means of shears, drills, saws, waterjet cutting, lasers, etc., hinge parts can be shaped.

Secondary Processes and Peripheral Treatments

In order to solve the problems of wear and tear, deterioration, and other problems that can occur over time, most manufacturers carry out secondary processes and peripheral treatments on the hinges they produce. For example, manufacturers use ball bearings to assemble the hinge components during the secondary process, in order to make the hinge move more smoothly. Finishing treatments such as painting, polishing or buffing are also widely used to improve the aesthetic and decorative appearance of the hinges. Anti-rust treatments, on the other hand, can extend the life of the hinge.

This article briefly introduces the stainless steel hinges manufacturing process – the common types of materials and processing techniques used for hinges. We hope it will provide you with some necessary assistance in sourcing hinges. Especially the fans of hinges and the intended customers of our hinges, let you know more about the entire hinge production process and increase your knowledge. If you have a deeper interest, we can provide you with a video of the stainless steel hinges manufacturing process, if you want to go further Understand, welcome to visit us, we will show you the hinge manufacturing process of our factory. We have adopted automated production equipment, which is competitive advantage equipment, so it cannot be shown here. It greatly improves production efficiency and saves costs, so we can better provide customers with lower prices and deliver on time.

Venace is specializing in kitchen hardware, kitchen cabinet accessories. cost control and quality control are our core, we can provide high-quality products at a low price. We welcome global distributors and dealers to send us inquiries. Our cabinet hinges include Soft Close Concealed Hinge and Soft Close Butterfly Plate Concealed Hinge, you can feel free to ask us for a catalog and make an inquiry.

Send us a Message Now

Get A Free Catalog and Price List of Our Hinges Today!!