How Door Hinges Are Made

The usability, effectiveness, and cost of various hinge pairs can vary significantly. The substances and procedures used to make hinges are the cause of this variance. Even though hinges were around for centuries, standardized hinge manufacturing companies did not emerge until the manufacturing and industrial machining age.

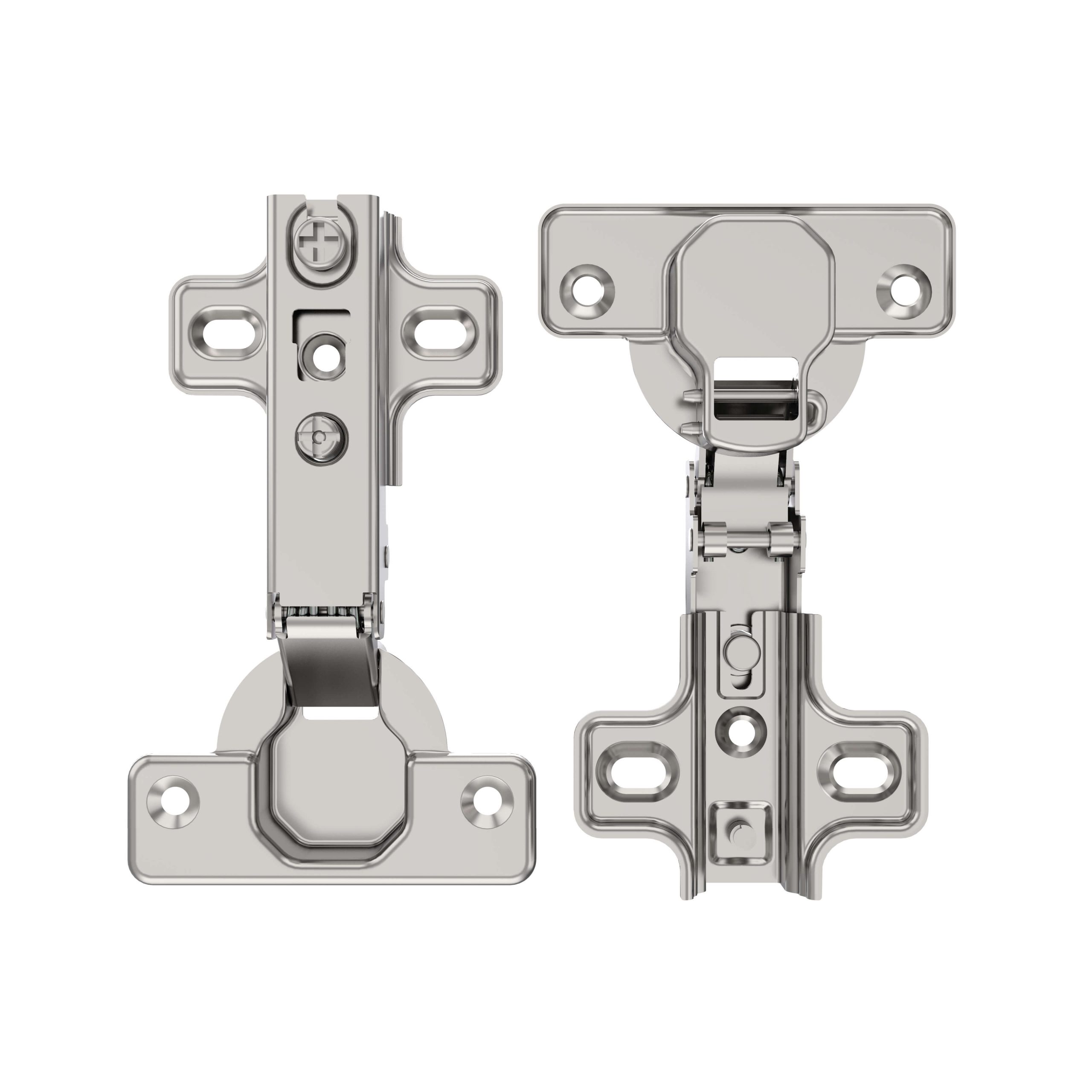

Making door hinges is a complex process. It includes the use of machines. The underlying materials, tools, and manufacturing techniques used to make different hinges are used to categorize them. Because steel is the prevalent material involved in hinge creation, metal fabrication techniques account for the bulk of hinge production methods. Whereas metal processing methods are common in other industrial operations, they have several features that set them apart in the hinge industry.

Explain the Manufacturing of Door Hinges

Hinges are the mechanical bearings that allow you to open doors and keep your room safe. These were not generally available until the advent of mass production and skilled machining, even though they had been in use for centuries. Blacksmiths used to forge hinges by hand over flaming containers, one at a moment. Hinges are now manufactured at a surprising rate to meet the requirements of people. Based on the steel required, the kind of door fitted, and the size of the door placed, each variety of hinge is built differently.

Hinge Production’s Major Stages

Hinge production is divided into two steps. The deforming and shaping of the metal part into the hinge element is the most common of these.

Treatment with Heat

Heat treatment is used in the fabrication of hinges in general. If you want to make moldable hinges, they need to be melted in a casting unit or an industrial oven. It is easy to mold the forming substance into a different form and alter its chemical structure by heating or boiling it.

Machine Processes

The following step involves machining the steel into the hinge part by flattening, stamping, deforming, or cutting it. Hinge parts are made using four different machining methods.

Hinges Secondary Manufacturing Processes

Following the major steps included in the hinge manufacture, several secondary procedures entail processing for wear and degradation resistance. When a hinge is utilized, for example, some of the metal wears away. As a result, some hinge manufacturing companies.

choose to assemble the hinge with ball bearings. The hinges can move more smoothly thanks to the bearing.

Blending, polishing, and painting are examples of finishing methods that can improve the artistic appeal of hinges. However, rust-proofing them can help to ensure that they last longer.

Materials for Hinge

The forming materials used in hinge manufacturing have a significant impact on the cost and uses of the hinges. Steel is the widely used metal due to its mechanical strength and flexibility. Steel, despite being a carbon-iron alloy, could be alloyed with some other metals to create complex materials.

For instance, stainless steel is made by combining steel with chromium, it has a strong rust tolerance and is ideal for hinges subjected to water or other acidic elements.

What Kinds of Materials are Best for Hinges?

Another frequent hinge-forming metal is brass. It’s a zinc-copper alloy that’s more malleable and has a lower thermal conductivity than both of its parent metals. Brass is suitable for constructing hinges with aesthetic uses because of its comparative ease of fabrication and yellowish-gold tint. Bronze, a tin-copper alloy, is also quite straightforward to work with and has a red surface hue that adds aesthetic appeal.

Bronze offers a lower metal-to-metal wear rate, making it perfect for hinge connection activities.

Many manufacturers utilize secondary procedures and peripheral modifications after a hinge has settled on the proper shape to assist prevent them from degrading over time. Many individuals are unaware that every time they utilize a hinge, a little percentage of the hinge’s material is eroded. To achieve a better sliding movement, some manufacturers build hinge parts with bearing between every joint.

Conclusion

Hardware production has changed a lot in the last several years, enabling you to keep on budget while yet getting the high-quality hinges you need for industrial and domestic applications. this overview of how hinges are created has provided you a great understanding of how the door hinges are manufactured by companies The more information you have, the easy it will be to select the best hinge for your needs.