How to Buy a Quality Gas Spring

Industrial gas spring has a different off-the-shelf and wide range of standard products available from several manufacturers. But when you order a gas spring from a catalog it can display various faults and risks too. Based on the application you must find the right spring. There are some better ways to get gas spring, you can take help from a professional engineer to get the design you want and use industrial material at the beginning.

Gas springs are maintenance-free, force-generating, and self-contained cylinders. They are used to transfer and position table tops, chairs, and lids. The body of the spring is charged with nitrogen gas which provides the specific outer force. Pressure is applied to the diameter and the piston area which provides the outer pressure in the push-type springs. Let’s get to know more about the design and customization of gas springs.

Basics of gas spring

To understand the main factors of gas springs you must know the basics. The body of gas springs is filled with nitrogen gas that produces the pressure. This pressure pushes the piston which provides the outer force in push-type springs. Some gas springs have vent valves to release the nitrogen to reduce the force of the spring. Based on the application you can choose from different types of gas springs. Some common types available in the market are:

- Push type:this is to lower loads and lift with easy control. Push type offers lids and covers in a broad range of industries.

- Pull type for tight fit:This is a compact type mount and unlike the standard push type, it gives pressure to the piston rod. Pull type has a low progression level. This is the increase in the outer force that can be 11%.

- Locking to hold the position: chairs sometimes need to maintain a position to support the person. In the case of an adjustable desk chair, a person will adjust the height of the chair by pressing on the lever or a button. The gas spring offers the level to the person and adjusts the position.

How to get the best performance from gas springs?

How to get the best performance from gas springs?

To get the best performance from the gas spring you have ordered, it’s crucial to understand the parameters of the selection process.

- Weight and size: Before you buy the gas springit’s important to know the weight and dimensions of the product. You can use a spring scale to check the weight.

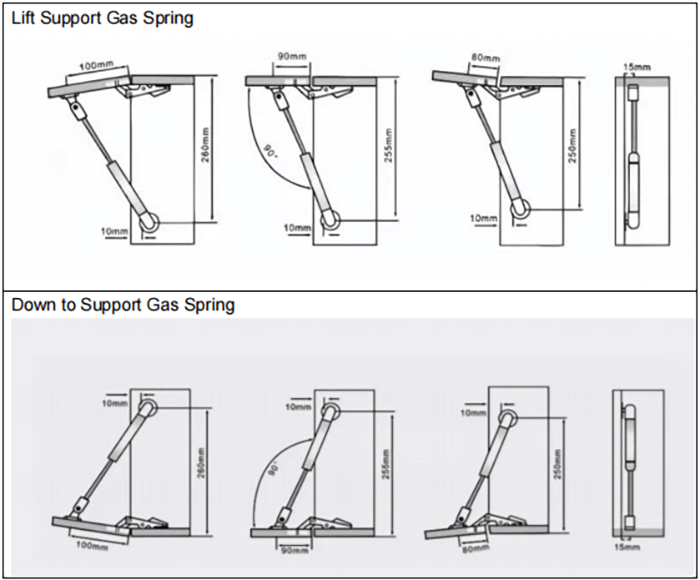

- Pivot point: This is the hinge and it offers support and this is the main part for the rotation of the covers and the hoods. You have to check if it’s at the bottom, middle, or the top of the gas spring. Orientation: The body of the spring must fit with the assembly without anything blocking the range of motion.

- Point of lifting: Check the point of lifting and determine where the user will pull or push to move the load.

- Finishing angle: This is the angle of the load when the gas spring finishes the movement.

- Starting angle:This is the angle of the load when the spring starts to move.

- Extension force: Forces are applied in gas springs to balance the hood or the load to move. Designers determine the level of nitrogen in the gas spring. Suppliers and manufacturers help customers to understand the balance.

- Hand force:This is the level of force the user has to apply to transfer the load. An engineer can help decide the required hand force for various angles.

- The center part: the center part is important to understand the rotation. This will counterbalance the load.

- Stroke length: Make sure that the gas spring can handle the entire force of the installation. Gas spring sellers have product data that offers different forces that interact with the stroke and determine the force required so the stroke can manage.

- Mounting: The mounting of the gas spring decides the opening angle of the loads and the distance the spring requires to transfer the load. This is known as stroke. You can ask the seller about this and they will provide the necessary information.

Other than these you also have to check the material and the ambient temperature. It’s best to take help from an engineer or ask the gas spring vendor to assist you.

How to get the best performance from gas springs?

How to get the best performance from gas springs?